A comprehensive review on oilseed cakes and their potential as a feedstock for integrated biorefinery

Abstract

In oil processing industry, large number of oilseed cakes remains after the extraction of oil. Oilseed cakes and meals are the residues would act as valuable feeds for livestock as it is rich in protein. These agricultural residues serve as a major valuable feedstock for cattle and used for the production of value-added products such as biogas, biofuel, biopolymer, antibiotics, enzymes, etc. The usage of oilseed cake as raw material would reduce environmental pollution as well as the production cost. This can be served as a potential solution to overcome nutritional problems in animals by enriching the nutrition using appropriate technologies. As the world moving towards sustainable fuel and chemical synthesis using renewable resources deemed as second-generation biofuel feedstock rather than fossil fuels, these non-edible oilseed cakes are used to produce biofuels with an integrated biorefinery perspective. The oilseed cakes plays vital role in the area of enzyme and fermentation technology. The fermentation process using fungi could act as relatively low-cost appropriate technology for upgrading nutrients in oilseed cakes. Oilseed cakes are rich in fiber and have a high concentration of non-starch polysaccharides (NSP) such as cellulose and hemicellulose (Xylan). Lipase and alpha-amylase are the two most essential enzymes produces by the oilseed cake. This review focuses on exploiting the various oilseed cakes and their commercial utilization by implementing various biotechnological approaches.

INTRODUCTION

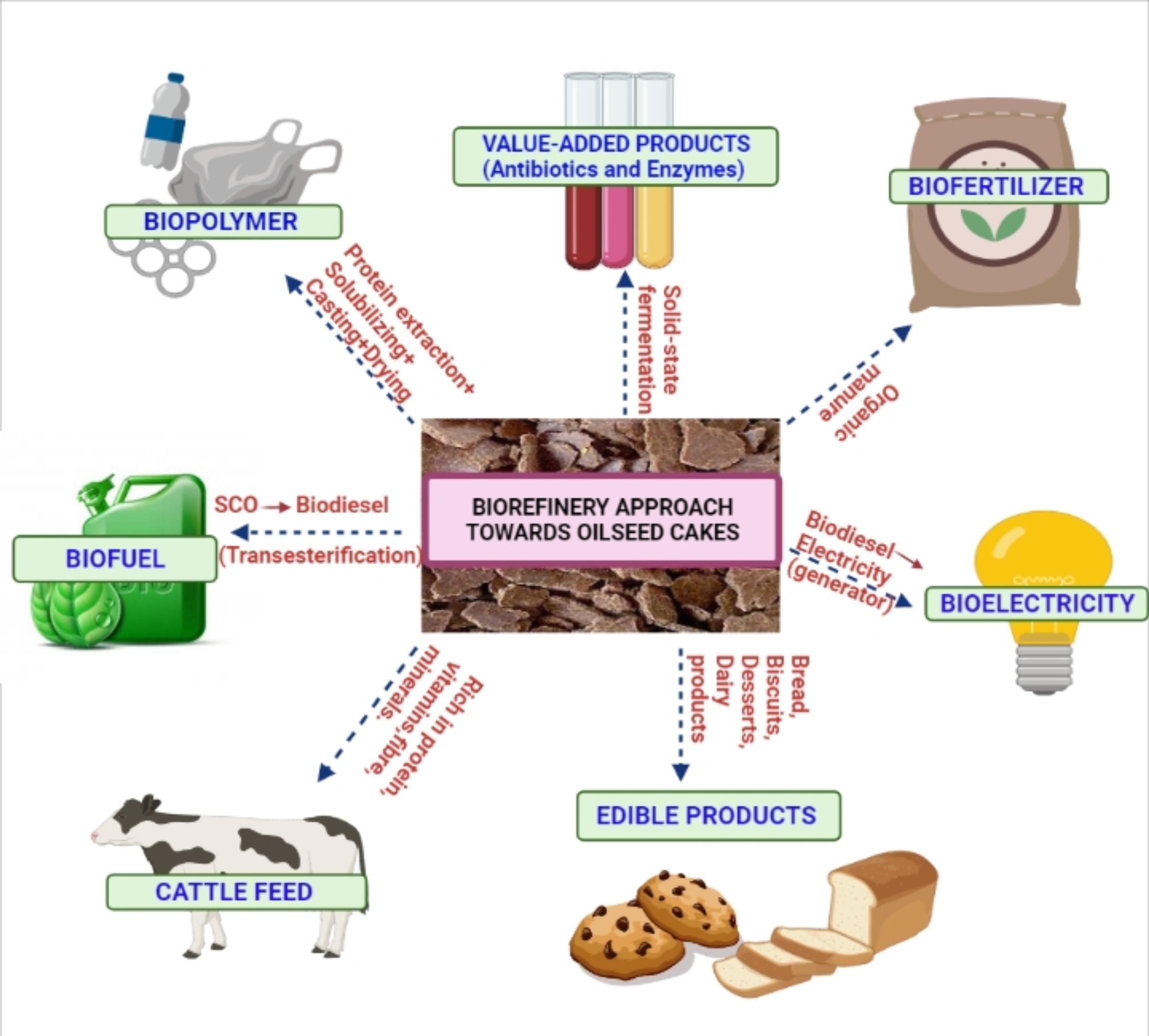

International requirement for edible oilseeds and nutrients can meet by engaging small-holder farmers in annual oilseeds production. Such production would create the domestic oil processing industries with total capacity [1]. The by-product of seed is found after extracting oil from the seeds, in which de-oiled part is called as oil seedcake. Oilseed cakes are the residues generated by pressing preceded by extracting a significant portion of oils from oilseeds and are considered as agricultural wastes or by-products. However, these can prove to be beneficial to animals and plants [2]. Oilseed cakes can be divided into edible and non-edible oilseed cakes [3]. Mustard, sunflower, soybean, mahua, peanuts are classified under edible oilseed cakes. These are highly rich in protein and contain various antioxidants, fibers, and vitamins and therefore, preferred as supplement feed for animals and sometimes beneficial for humans. In addition, major bakery products are being produced with sunflower oilseed cakes [4]. Whereas, jatropha, castor, neem, sesame, and simarouba are considered as non-edible oilseed cakes because of a high amount of toxic compounds after the oil being extracted from the seeds [5]. Oilseed cakes are used for the production of bioenergy, biopolymer, pesticides, and bioelectricity [6]. A biorefinery is a process of converting biomass into energy and high-value beneficial products. The concept of biorefinery could develop quickly in the production of bio-based products i.e., food, feed, chemicals, and/or materials and bioenergy that includes biofuels, power, and/or heat. It can be represented as more economical option for bio-based chemicals such as citric acid, succinic acid and sugar alcohols which are the co-products of fuel synthesis [7]. The advantage of biorefineries in an integrated perspective is to minimize the agricultural waste products and maximize the value-added products. Most of the oilseed cakes are currently used as animal feed or plant fertilizers. It represents an attractive feedstock for the development of new bio refinery. Protein added-value products can be generated by oilseed cake. The proteins from oilseed cake could be turned into renewable sources for producing bioplastics [8]. Figure 1 shows oilseed cakes in biorefinery aspects. Oilseeds are cultivated over 2836 million hectares annually across the world and 29 million hectares in India [18]. Among the global countries, Australia, Brazil, Canada, the USA, India, and the EU are major producers and exporters worldwide [19]. Oilseed processing and extraction of oil can be done using two different methods, i.e., hot press and cold press. In hot press processing, extraction of oil followed by applying high temperature on the oilseeds. Hot press processing is the conventional practice as volumetric oil production is high, and the disadvantage is the loss of heat-labile components like protein, amino acid, vitamins, etc. [9]. In cold press processing, extraction of oil followed by without applying the heat on the oilseeds, wherein the health benefits nutrients are retained [10]. The majority of the oilseed cakes available in the market are hot-pressed ones. The cold press extraction of oils yields a high quality of oils (and oilseed cakes) and it is environmental friendly as it does not involve any usage of heat and chemical solvents for extraction. People are gradually shifting from hot-pressed to cold-pressed oils as they retain a higher portion of heat-labile components like vitamins and antioxidants with higher nutritive value than refined oils [11].

Cold-pressed processing contains more oil remains than solvent-extracted or expeller-pressed. Solvent extraction and expeller pressing are well-organized oil extraction methods than cold pressing method, and less heat is applied to the seeds during cold pressing than solvent extraction or expeller pressing [3]. In current scenario, Jatropha (Jatropha curcas), Karanja (Pongamia pinnata), Safflower (Carthamus tinctorius),cottonseed (Gossypium hirsutum) are used for biofuel production [12-14]. The extraction of oil from these oilseed cakes generated vast amounts of the remaining de-oiled seed cakes. In Jatropha, about 1000 kg of seed cakes/hectare of the crop is generated for 2500kg seeds/ hectare of the crop under normal climatic conditions [15]. Karanja that belongs to the Leguminaceae family is abundantly available in the wetland that is non-edible. The estimated productivity is 0.145 million metric tons of oilseed cake per annum [16]. An increasing focus for reducing the cost of various industrial processes, the low-cost oilseed cake would fits this criteria could act as effective way for utilizing agro-waste [17].These also includes enzyme production by being highly proteinaceous, bio-pesticides production, and can utilize as an alternative source of fuel for bioethanol production through fermentation technology [18].

SOURCES OF OILSEEDS

Soya bean oil finds a prominent position with production amounts of 337.9 million tons, followed by sunflower, cottonseed, rapeseed is 56.6, 43.4,73.1 million tons, respectively [20]. India is the second-largest producer of groundnut in the world and third-largest producer of rapeseed oilseeds [9]. In India, the primary quantity of vegetable oil produces from nine oilseeds that are majorly grown in 26 million hectares of area. Soybean, groundnut, mustard contribute more among total oilseed production and as >80% of vegetable oil. Andhra Pradesh, Gujarat, Karnataka and Tamil Nadu are the major producer of groundnut oilseed, whereas, Haryana, Uttar Pradesh and West Bengal are the major producers of mustard seeds and Madhya Pradesh, Maharashtra and Rajasthan produces a high amount of Soybean seeds. These are the major states that contribute more than 95% of total oilseed production in the country [22]. Apart from nine primary oilseeds, 3 million tons of vegetable oil is being extracted annually from cottonseed, rice bran, coconut, Tree Borne Oilseeds (TBOs), and Palm [13]. The oil cakes product from oilseeds would be obtained by using different processing method. Table 1 shows oilseed production in different states of India. Generally, bioactive compounds could also obtain from oilseed cakes, such as carbohydrates, protein or amino acid, etc. The best use of the oilseed cakes would depend on the amount of nutrient factor and concentration present in the sample and method of extraction process [23].

Table 1. Oilseed production in different states of India (2015-2016*). Source: Agricultural Statistics at a glance 2016.

EXPLOITATION OF OILSEED CAKES AND THEIR COMMERCIAL UTILIZATION BY FERMENTATION PROCESS

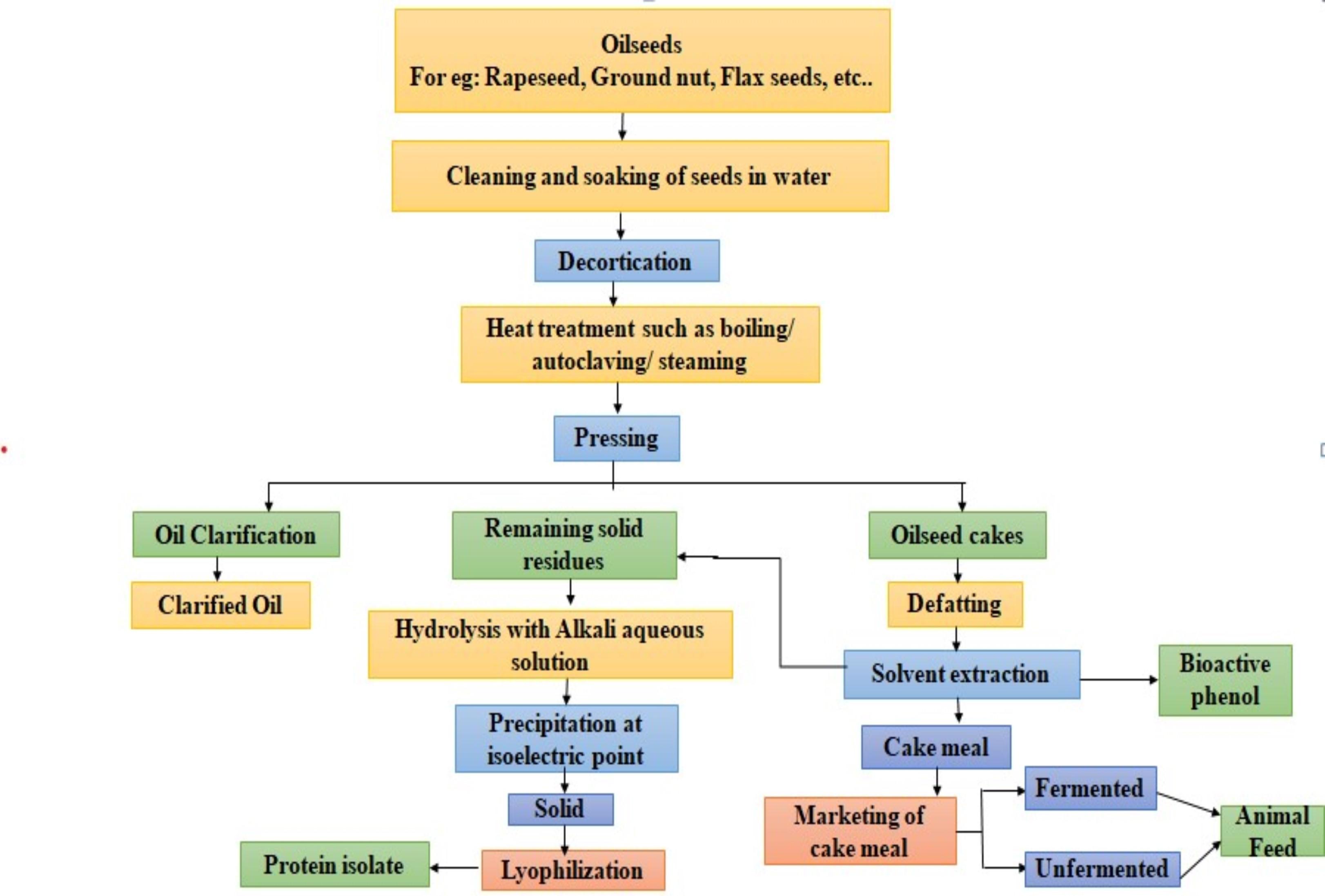

The oilseed cakes would be utilized for commercial production of enzyme, biogas, antibiotics, biopolymer, bioelectricity, etc. In the field of bioprocess, oilseed cakes would give potential benefits when it is utilized as a substrate [24]. Solid-state fermentation is a biotechnological process in which organisms would grow on a non-soluble substrate or solid material in the absence of free-flowing water. This process could be used for converting the oilseed cake into a beneficial product [25]. Antibiotics are produced by different microorganisms, which selectively kill the microbes or inhibits low concentration growth [26]. Other utilization of oilseed cake is oncom production produced by peanut cake. It is an indigenous fermented product from Indonesia [27] Figure 2 shows the processing of oilseeds and extraction of oil in the oil processing unit and usage of oilseed cake for ruminants feeding.

COMMERCIAL PERSPECTIVE OF NON-EDIBLE OILSEED CAKES

Biogas and biofuel production

Plant biomass could be a sustainable source for the production of biofuels, most commonly bioethanol. Ethanol can act as an alternative substitute for non-renewable limited sources like petrol and gasoline. In current world, ethanol is produced by the fermentation of sugars from fruits, molasses, and cereals [7]. According to research carried out by Doshi et al.[15], 100g of Karanja kernel could produce 0.21L of ethanol, whereas a mixture of kernel and hull could produce 0.16L of ethanol, which was significantly greater than other commonly used crop residues like corn stover, barley straw, sugarcane bagasse, wheat straw, etc. However, the Karanja hull was shown to be an inefficient substrate for the production of bioethanol. In this study, the oil extraction using a mechanical grinder and solvent extraction using hexane, pre-treatment of the residual oilseed cake was carried out by heating at 121 °C for 90 min with a pressure of 15 psi, followed by centrifugation. Acid hydrolysis using 5% sulfuric acid was done, followed by fermentation using yeast under anaerobic conditions for up to 9 days [27].

Ammonia fiber expansion (AFEX) is a mild pre-treatment method when compared to other pre-treatment methods. In this study, enzymatic hydrolysis done to release the simple sugars followed by fermentation using P. stipitis Y7124 [28]. The glucose concentration of 26g/L was obtained after hydrolysis, along with 13g/L of the remaining sugars. The amount of ethanol produced after 24 hours of fermentation was found to be 15.2g/L. However, prolonged fermentation showed a decline in ethanol concentration. It was found that approximately 0.4g of ethanol production consumed 1g of sugar [29].

Oilseed cakes are commonly known as agricultural wastes. The two methods used for oil extractions are solvent extraction and mechanical extraction [30]. The former uses a mechanical extraction such as a rotary machine, and later uses solvents extraction to produce biogas, mainly nonedible oil seedcakes is used [20]. Most of the non-edible oilseed cakes, such as cottonseed, karanja, castor, neem, and mahua are used as organic fertilizers due to their nitrogen, phosphorous and potassium content [21]. Recent research and development shows interest in producing biogas with oilseed cakes. Some researchers investigated the effect of pre-treatment methods, operation parameters, and type of inoculums used for biogas production [19]. The anaerobic digestion method is used to produce biogas from de-oiled cakes [31]. The lignin content in the biomass controls the productivity of bioconversion [32]. Some functional and physicochemical properties have been used to overcome the low availability of biodegradable content in lignocellulosic biomass [32]. Jatropha curcas seed cake is one of the most suitable by-products for biogas. Anaerobic digestions for biogas production were conducted in laboratory conditions at 37 °C in a 5 L glass fermenter with a combination of different seed cakes with cattle dung [12]. Biogas production was estimated at several hydraulic retention times (HRTs), as much as 265 L/kg of cakes obtained with the methane concentration around 65% that resulted in 2550 million cubic meters of biogas [33].

Enzyme production

Non-edible oil cakes are potentially used for biotechnological applications, for example, bioenergy, biopolymer, etc. Several reports describe a protein, enzyme, and pesticide production using non-edible oil cakes such as castor bean residue and Jatropha as substrates in solid-state fermentation. According to the study [20, 34], the biomass was utilized during solid-state fermentation for protease production by using Aspergillus niger. Proteases are industrial essential enzymes produced in comprehensive pharmaceutical companies and research fields. Lignocellulolytic enzymes such as cellulases and xylanases play a critical role in depolymerization of structural carbohydrate polymer into monomeric sugars. Cellulases play a significant role in winery, laundry, brewery, textiles, and paper industries. Increased demand for proteases and cellulases in agro-industrial applications has put pressure on these enzymes production systems. The study by Nagegowda et al.[36] attempts to address the management of two de-oiled seed cakes, Madhuca indica (Mahua) and Jatropha curcus (Jatropha), via solid-state fermentation, producing proteases and cellulases as value-added products. Aspergillus niger and Paecilomyces variotii were chosen for protease and cellulose production based on their ability to grow on the de-oiled seed cake. According to Mahanta et al.[37], in jatropha seed cakes, initial moisture content of 50% and temperature at 30°C, maximum protease activity of 52.5 U/g, and cellulase activity of 27.3 U/g were recorded in 5 gram of seed cake from A. niger and P. variotii, respectively. For the production of the enzyme, solid-state fermentation have been used. Solvent tolerant Pseudomonas aeruginosa PseA strain was used for fermentation [38]. The seed cake supported good bacterial growth and enzyme production (protease, 1818 U/g of substrate and lipase, 625 U/g of substrate) [35].

Simarouba belongs to the family Simaroubaceae. It was also known as the paradise tree, Laxmitaru, Acetuno, a multipurpose tree that can grow well under a wide range of hostile ecological conditions. It is source of both edible oil and biofuels. The oil cake is valued as organic manure, which is very rich source of protein [39]. Simarouba de-oiled-cake can also be used as a substrate for the production of lipase from Aspergillus niger in MGM media. This enzyme was produced by solid-state fermentation method. Partial purification of the enzyme was done by precipitation using ammonium sulfate, and the pellet formed was found to be precipitated maximum at 20-60% concentration of ammonium sulfate [40].Sal (Shorea robusta) de-oiled seed cake is obtained after oil extraction from sal seeds, one of the important non-timber forest products used for extracting oil/fats, which have diverse applications in commercial food-based industries [41]. This might induce excessive exploitation of sal seeds, resulting in a huge quantity of de-oiled seed cake. Sal de-oiled seed cake could be considered as a prominent inducer for protease production. After optimization, a significant yield of protease was obtained by Aeromonas sp. S1, with this cheaper and abundantly available biomass and can be further used as an economical source of protease production [42].

Lipase production was first reported by the usage of sesame oil cake by Penicillium sp. and Aspergillus niger using gingelly oil cake as substrate [29]. Lipase production in sunflower oilcake using Pseudomonas gave a maximum enzymatic activity as 540 U/mL at 60ºC at a pH of 8. Other seedcakes like coconut, groundnut, olive oilseed cakes were used as substrates for phytase production using Rhizopus sp. Mixed substrate fermentation using coconut oil cake and sesame oil cake resulted in increased production (almost two-fold) of phytate (64 U/gds phytases) when compared to the use of only coconut oil cake and sesame oil cake [43]. An extra-cellular alkaline protease was produced by Bacillus horikoshii using soybean cake as a stable substrate around a wide range of pH (5.5 to 12) [44]. Coconut oilseed cake along with wheat bran fermented by A.oryzae produces neutral metalloprotease [36]. Coconut oil cake was used to produce amylase (1827 IU alpha-amylase/gds) using A.oryzae [45]. The study [46] reported palm oil cake and palm kernel cake were used for various enzyme production by using A. niger.

Antibiotics production

Sircar et al. [49] reported that antibiotics can be produced successfully by fermentation process using suitable microorganisms when oilseed cakes were used as substrates. Using solid-state fermentation for antibiotics production is more energy-efficient than the other conventional methods like stirred fermenters. The maintenance of the parameters like foaming control, continuous agitation, and air supply add to the energy requirements and cost [50]. Studies carried out by Sircar et al.[49] show the utilization of sunflower, soybean, and sesame oilseed cakes to produce clavulanic acid and cephamycin. When fermented with Streptomyces peucetius, Seasame oilseed cake act as an efficient C-source for microbial growth. By using phosphate buffer, it shows high productivity of antibiotics, faster and more efficient conversion of intermediates into its final products [50]. Ramachandran et al. [45] report shown that the usage of sunflower oilseed cake for cephamycin C production. The study carried out by Farzana et al. [47] showed the synthesis of antibiotic bacitracin by fermenting it with Bacillus licheniformis using oilseed cake as the substrate. Results showed a maximum potency obtained in soybean oilseed cake, followed by the wheat meal, sunflower oilseed cake, and the least productivity in rice hulls.

Biofertilizers

The cottonseed plant is growing in subtropical and tropical regions worldwide, including Africa, America, India, etc.[27]. Bangladesh is one of the most cotton seed-producing countries. In this country, the cotton (silk cotton) plant, the Gossypium herbaceum, is found in almost all Bangladesh districts [51]. Chemical fertilizer has raised the issue, and it is very hazardous for public health, environment, and soil fertility. Various research and studies shows how to utilize organic fertilizer which is a good alternative to chemical fertilizer , especially in developing countries [13]. Organic fertilizer converts nitrogen in a less soluble form is the main advantage in comparison to chemical fertilizer. Plant and weed necessitate energy in the chemical form to easily grow and carry out all the basic life and function like all other living creators. Cottonseed cake has all the nutrient fertilizers required for plant fertility. Cottonseed cake is having ash content, moisture content, mineral content, carbohydrates, etc. Apart from this, almost 10 elements, i.e., Na, K, Ca, Mg, Fe, Zn, Cu, Pb, Mn, and Ni were investigated from cotton oilseed cake by AAS (Atomic Absorption Spectroscopy), which are responsible for the growth of plants, weed herbs, etc. [13].

APPLICATION OF NON-EDIBLE OILSEED CAKES

Bioelectricity

Some of the non-edible oilseeds contain anti-nutritional factors, or sometimes it is poisonous. The use of non-edible oil for biodiesel and the remaining part, like oilseed cake, is used as a biopesticide, bioelectricity and for various applications. In some rural areas, where electric facilities are not available, whereas biomass-producing bioelectricity would be very helpful. The study done with jatropha oilseed cake shows that the electricity-generating machine has consumed up to 4 to 5 kg of oilseed briquettes per hour and generate up to 4.5 kW of power [52]. The process of bioelectricity production with oilseed cakes and biodiesel, biogas production by using Jatropha as a biomass by preparing briquettes and then used. According to the American standard, the property of briquettes are length, diameter, calorific value, compressive strength, and density were determined [53].

Bioactive compounds

The plant contains primary and secondary metabolites whereas, oilseed cakes contain secondary metabolites such as flavonoids and phenolic acid. The extraction process of bioactive compounds was done by direct bio-autography. High-performance thin-layer chromatography (HPTLC) is a rapid and straightforward technique for determining and characterizing complex and crude extracts [25]. The various advantage of HPTLC is low operating cost, simple sample preparation, simultaneous analysis of several samples, and short analysis time [40]. The extractions of polyphenol of flex and canola oilseed cakes are determined. It shows separate biochemical compounds in canola oilseed cakes slightly high in comparison to flax seed cakes [54]. Vidyarthi et al. [52] reported the growth of Bacillus thuringiensis (Bt) and its endotoxin production in sesame oil cake-based commercial medium was comparable (spore count) to that in the laboratory [56]. Tuli et al.[53] observed that the addition of mustard oilseed cake (6%) in the whey permeate medium led to the increased lactic acid conversion among the immobilized cells. Ohtsuki et al.[54] reported that Bacillus circulans strain YUS-2 was the strongest antioxidant-producer using sesame oilseed cake as substrate.

Biopolymer

The biopolymer generated from sunflower oilseed cakes, when applied the thermo-mechano-chemical with a twin-screw extruder for the by-product fractionation. It differentiates into three phases, the upper hydrophobic phase, the hydrophilic phase, and the remaining cakes [42]. The cake could be used as animal feed or for bioenergy production in pellet boilers. However, part of the proteins in the cake is globulins, revealed a thermoplastic behaviour. It is also shown as a natural composite and flexible into the self-bonded products, using the thermo-pressing method, such as fiberboards [55]. The valorization of oilseed cakes is confirmed by a recent market study, and the global market for agro-materials is active for the growth order of 50 to 100% per annum. The application of self-bonded fiberboard is bags, building applications and furnitures, etc. The advantage of this biopolymer is environmental friendly, renewable, and biodegradable at the end of life [56]. The handling such as machining and cutting are easy to implement. Thus, using the by-product of oilseeds to produce agro-materials by thermo-pressing looks like an innovative and advanced solution for valorization [25]. Initially, they studied the thermo-mechanical property of cake, DSC (Differential Scanning Calorimetry) measurements shows the denaturation of protein in the cake and DMTA (Dynamic Mechanical Thermal Analysis) spectrum of the cake showed the significant peak at high temperature (175–200 ◦C) [25]. It is also linked with a glass transition of protein, then it was detected with the help of PVT pressure, volume, and temperature analysis in 180◦C and the mixture of plasticized protein and lignocellulosic fiber [57]. The oilseed cakes are the natural composite, and it is successfully processed to polymer fiberboards, and protein increases the consistency and entanglement of fiber [42].

Cattle feed

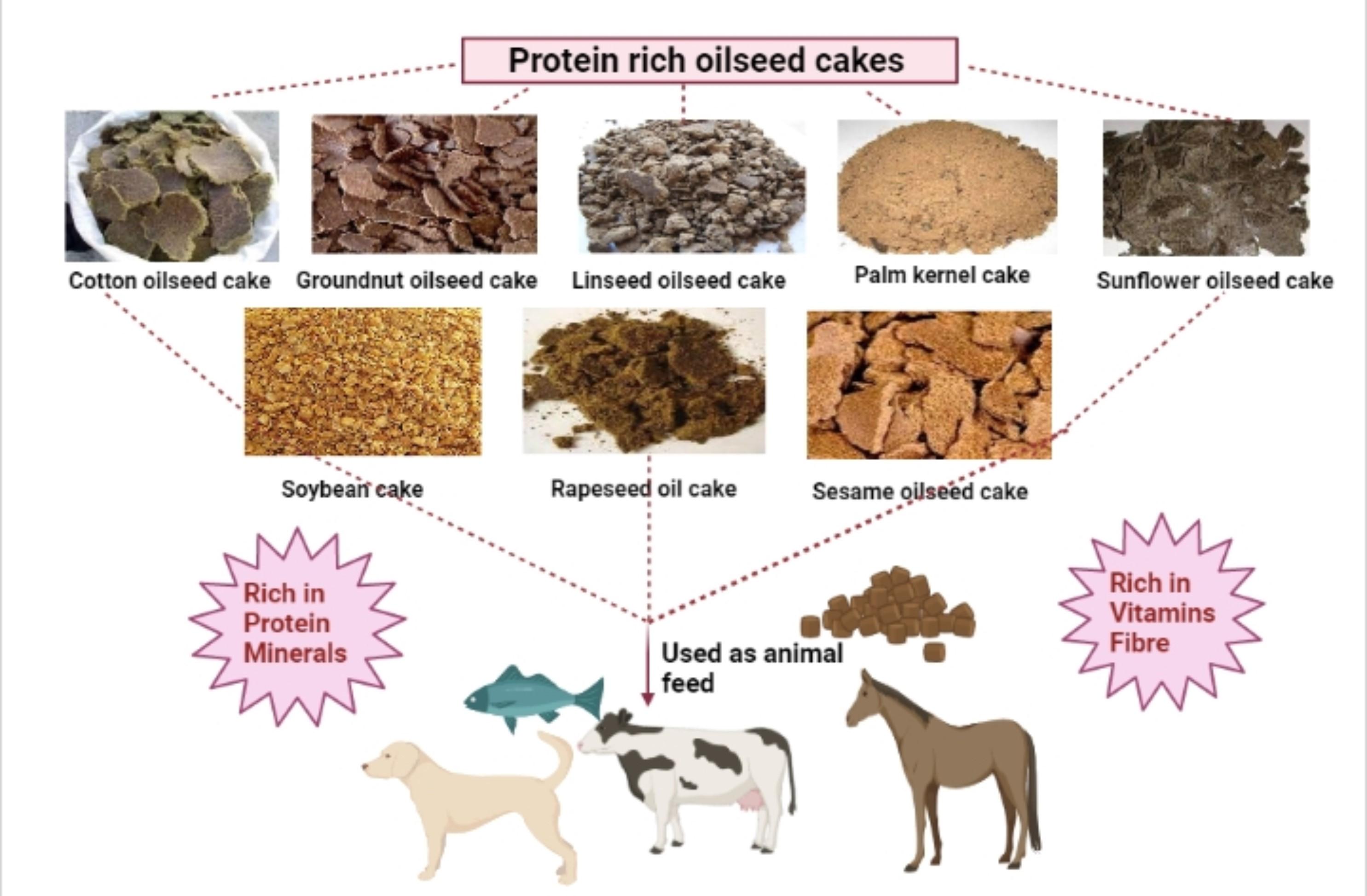

Edible oilseed cakes are the agro waste which generate during the processing of oilseeds. It is useful for animal feed, for example, young calves fed hempseed cake had similar live weight gain to calves fed with a mixture of soybean meal and barley [58] along with some bakery products. Hempseed cakes have favourable amino acids, and the protein resists degradation in the rumen [59], which can offer some advantages as animal feed. Furthermore, Hempseed cake was used as an aquaculture feed for farmed fish [60]. The addition of hempseed cake into fish meal improved the texture of fish fillet [61] and fish growth rate [62]. These oilseed cakes can be processed and made more palatable and edible by suitable treatments and then incorporated as food supplements for human consumption. Being rich in proteins, antioxidants, fibers, vitamins and minerals, oilseed cakes have been considered ideal for food supplementation [23]. Their chemical composition varies due to the differences in oil extraction methods. Oilseed cakes such as palm kernel cake, sunflower, and mustard cake contains 14–20 % of crude protein [63]. Groundnut cake contains 40–50 % of crude protein and can produce fine value-added products. Oilseed cakes are rich in protein contents and can be utilized to develop new products and fortify products such as ionophore nut-based biscuits [64], and shelf-stable bread-spread from African oil bean seeds [30]. Animal feeds consist of carbohydrates, fats, oils, and proteins together with smaller amounts of minerals and vitamins essential for the proper functioning of the body’s metabolic processes. The quality of the protein in oilcake is considerably higher than that of cereals, but it tends to be more of inferior quality than animal protein. Figure 3 shows various kinds of protein rich oilseed cakes used as animal feed. Along with the cost, the major decisive factor for using a particular oilseed residue depends on the amino-acid composition of the cereal and cereal by-products incorporated in the diet. Oilseed cake may significantly contribute to the animal diet’s energy content, mainly when the oil content is high [65]. The nutrient content in these oilseed cakes also depends on the production process. Most of the animals eat mainly grain and husk, and these oilseed cakes can be provided as a supplement. These supplements contain various proteins, electrolytes, vitamins, etc., that enhance these animals’ performance productivity. In addition to these, the fats present in oilseed cakes are a good source of linoleic acid that improves farm animals’ metabolism. In humans, these oilseed cakes are still not used prevalently as animals’ feed owing to the presence of certain anti-nutritional, which can be reduced by fermentation [66].

Oilseed cakes usually have high phosphorus content and low calcium content. They contain only negligible amounts of vitamin A-active materials, vitamin D, and vitamin B12 [67]. The fat in oilcake is usually an excellent linoleic acid source, essential for animal metabolic processes. Oilseeds may contain several toxic or undesirable substances, which may pass unaltered into the oilcake [68]. These substances may be natural constituents of the seeds, such as gossypol and cylopropenoid fatty acids in cottonseed, cyanogenetic glycoside in linseed, sinigrin or sinalbin in mustard seed, saponin in Shea nuts, the trypsin inhibitor in soybeans, or toxic mold metabolites, such as aflatoxin, which may be formed if the seeds are allowed to spoil by molds [42]. The effect of these undesirable factors can be reduced by restricting the amount of the particular oilcake present in the animal’s diet, by heating or steaming the oilcake, by extracting it with water, or by using oilcake from decorticated seed [67]. The processing, mainly if heat is involved, may lower the protein’s digestibility and denaturation, with a consequent lowering of its nutritive value [69].

Oilseed cakes as edible products

In some countries, dehulled sunflower seed are available in the market in a roasted form and used for bakery and sweets items. Nutritional sunflower cakes use as recipes for human consumption [4]. The dehulled oil cake powder was used in the recipes around 10 to 20%. The recipes like chapatti (a shallow fried item), bakery (a baked item), and pakodi (a deep-fried item) were prepared using oil cake powder and tested in the albino rats shows that the dehulled oilseed cake has more fat and protein whereas partially dehulled cake has more fiber content, fat, and protein [4]. When comparing both the chapattis with wheat flour and with 10 to 20% of oil cake powder, the modified chapattis have a high amount of protein fiber and fat content whereas lower the carbohydrates amount, the digestibility and growth-promoting ability are also increased following the PER (protein efficiency ratio) and digestibility coefficient methods [13].

Oilseed cakes would allow an extensive growth of mycelia due to their presence of high protein, fiber, nitrogen, energy, and residual oil [10]. Co-utilization of rice straw and oilseed cakes like cottonseed cake, mustard, soybean, and sunflower oilseed cake could be used as a potential substrate for mushroom growth Pleurotus sajor-caju. The supplementation with these oilseed cakes improved the results drastically and boosted the yield from 50 to 100%. This is due to the extra organic nitrogen that was supplied from the oilseed cakes. The addition of oilseed cakes also improved the rice straw’s solubility and enhanced the levels of free amino acids [20]. Sunil et al. [68] used mushrooms’ mixed culture to check the efficiency of growth in each of them. The maximum fungal growth was observed in soybean oilseed cake, which was found to be particularly rich in protein, carbohydrate, vitamin B, fat. However, the least growth was obtained in case of the worst results were obtained with pumpkin seed cake, mustard seed cake, walnut cake, milk thistle seed cake, and rosehip fruit cake. Mustard and soybean oilseed cakes (as supplements) combined with rice straw colonized by Pleurotus sajor-caju led to increased mushroom production compared to the unsupplemented rice straw. The supplementation using oil cakes had also resulted in increased solubility of rice straw, increased concentration of free sugars and amino acids, and decreased cellulo-hemicellulosic content [70].

Other industrial uses

Mahua oil cake, obtained after extraction, has a high concentration of saponins (4-8%), along with 8-12% oil, 15-17% protein, 50-55% carbohydrates, 5-6% fiber and 6-7% minerals. For the cake to be utilized as a feed, saponins need to be removed [23]. With the presence of saponins, mahua meal serves as a good wormicide and has insecticidal properties. It is also used in hair and bath care owing to its high sapogenic activity. Mahua oil is used as a substitute for tallow during manufacturing of soap [34].

CONCLUSION AND FUTURE PROSPECTS

Oilseed cakes are rich in nutrient content such as fibre, protein, and energy as they give possible benefits when used as a by-product in the production of various organic chemicals, bioenergy, and biomolecule. Further studies, need to be done on the extraction, utilization, and incorporation of dietary fiber and antioxidants in food products. Edible oilseed cake uses as a feed source, while non-edible oil seed cake is used mainly for bioenergy and pesticides. The use of oil cake for various products is good for environmental pollutions. The key point is that oilseed cakes are attractive due to their availability and relatively cheaper. The production of biogas and biodiesel are very important for economic development, and all the research indicates that the utilization of oil processing factory waste as biomass and generate beneficial products is helpful, efficient, and cost-effective. If the production of biodiesel and biogas is coupled with each other, the seed cakes provide very feasible commercial investment. Research shows that different waste to be used to produce bioenergy such as agricultural waste, wastewater sewage, etc. but the oilseed cake is one of the most attractive ways to produce biogas. And same in the term of cattle feed to be produced with oilseed cake is need to acquire depth knowledge. The cattle feed rate is increasing every year because insufficiency of farmlands to grow the feed. Thus, the cattle feed production from oilseed cakes concerns feasible and beneficial as well as it would reduce the environmental pollution and make it eco-friendly.

LIMITATIONS OF THE STUDY

Due to anti-nutritional property, the direct utilization of oilseed cakes in human or animal nutrition is limited, that influences the digestibility of protein, and bioavailability of macro-/micro-elements. The majority of oilcakes such as sesame, groundnut, rapeseed, sunflower, soybean, hempseed contain anti- nutrients such as phytic acid and trypsin inhibitors, which can diminish protein and utilization of vitamins. Further studies, need to be done on the extraction, utilization, and incorporation of dietary fiber and antioxidants in food products. Until now, the researchers have highlighted the possibility of adding appropriate amounts of by-products from oil-industry as functional ingredients in bakery, and dairy products without influencing negatively the quality of the final products. More investigations are required at the molecular structure and additionally, there are limited studies about the rheological properties of dough with different oilcakes levels and particle sizes.

ACKNOWLEDGEMENTS

This research received no external funding. The authors would like to extend their acknowledgement to the Department of Biotechnology, School of Bioengineering, SRM Institute of Science and Technology, Kattankulathur, Tamil Nadu, India.

AUTHOR CONTRIBUTIONS

AAS, NS, DC, RD, SDB and PA contributed to drafting the article. SJ contributed to revising it critically and final approval of the version to be published.

CONFLICTS OF INTEREST

There is no conflict of interest among the authors.

References

- [1]Caverzan A, Casassola A, Brammer SP. Antioxidant responses of wheat plants under stress. Genet. Mol. Biol. 2016; 39(1):1–6. doi: 10.1590/1678-4685-GMB-2015-0109.

- [2]Nicholson JK, Holmes E, Kinross J, Burcelin R, Gibson G, Jia W, et al. Host-gut microbiota metabolic interactions. American Association for the Advancement of Science. 2012; 336(6086):1262–1267. doi: 10.1126/science.1223813.

- [3]Jangir M, Sharma M, Sharma S. Synergistic effect of oilseed cake and biocontrol agent in the suppression of Fusarium wilt in Solanum lycopersicum. Brazilian J. Microbiol.2020; 51(4):1929–1939. doi: 10.1007/s42770-020-00344-8.

- [4]Sunil L, Appaiah P, Prasanth Kumar, PK, Gopala Krishna GK. Preparation of food supplements from oilseed cakes. J. Food Sci. Technol. 2015; 52 (5) 2998–3005. doi: 10.1007/s13197-014-1386-7.

- [5]Dias ALB, Sergio CSA, Santos P,Barbero GF,Rezende CA, Martínez J. Ultrasound-assisted extraction of bioactive compounds from dedo de moça pepper (Capsicum baccatum L.): Effects on the vegetable matrix and mathematical modelling. J. Food Eng.2017;198:36–44. doi: 10.1016/j.jfoodeng.2016.11.020.

- [6][6] Naik KS, Saxena SN, DK, Dole BR. Potential and Perspective of Castor Biorefinery. In Waste Biorefinery, Elsevier. 2018;623–656. doi.org/10.1007/s13399-021-01292-5

- [7][7] Salah HB, Allouche N. Plant-Based Chemicals Extraction and Isolation. Springer, Singapore. 2019;89-117. doi.org/10.1007/978-981-13-3810-6_4

- [8]Sarker S. Exploring biogas potential data of cattle manure and olive cake to gain insight into farm and commercial-scale production.2020; 32(106045).

- [9]Rai SK, Charak D, Bharat R. Scenario of oilseed crops across the globe. Plant Arch. 2016;16(1): 125–132. doi.org/10.1186/s42834-020-00051-x

- [10]Serrapica F, Masucci F, Raffrenato E, Sannino M, Vastolo A, Barone CMA, et al. High fibre cakes from mediterranean multipurpose oilseeds as protein sources for ruminants. Animals. 2019; 9 (11):1–11. doi: 10.3390/ani9110918.

- [11]Çakaloğlu B, Ozyurt VH. Cold press in oil extraction. A review. Ukr. Food Journal. 2018;7(4): 640–454. doi:10.24263/2304- 974X-2018-7-4-9.

- [12]Choudhury AR, Sharma N, Prasad GS. Deoiledjatropha seed cake is a useful nutrient for pullulan production. Microb. Cell Fact. 2012;1(11): 3–11. doi: 10.1186/1475-2859-11-39.

- [13]ziz S, Abu Bakar Siddique M, M. Hosney Ara Begum M. Cotton Seed oil cake as a valuable Source of Plant Nutrients for Sustainable Agriculture. Pharm. Chem. J. 2018;5(3): 39–45.

- [14]Hashemi SS, Mirmohamadsadeghi S. Biorefinery development based on whole safflower plant. Renew Energy. 2020; (152): 399–408.

- [15]Doshi DM, Srivastava P, Pathak G. Physicochemical and thermal characterization of non-edible oilseed residual waste as sustainable solid biofuel. Waste Manag. 2014; 34(10):1836-1846.doi: 10.1016/j.wasman.2013.12.018.

- [16]Dhyani SK, Vimala Devi S, Handa AK.Tree Borne Oilseeds for Oil and Biofuel. Technical Bulletin 2/2015: ICAR-CAFRI, Jhansi,2015, pp: 50.

- [17]Sadh PK, Duhan S, Duhan JS. Agro-industrial wastes and their utilization using solid-state fermentation: a review. Bioresour. Bioprocess.2018 ;5(1):1–15. doi:10.1186/s40643-017-0187-z.

- [18]Yang D, Park SY, Park YS,Eun H, Lee SY. Metabolic Engineering of Escherichia coli for Natural Product Biosynthesis. Trends Biotechnol. 2019;38(7):745–765.doi: 10.1016/j.tibtech.2019.11.007.

- [19]Sriti J, Neffati, Msaada K, Talou T, Marzouk B. Biochemical characterization of coriander cakes obtained by extrusion. J. Chem. 2013. doi: 10.1155/2013/871631.

- [20]Mohanty A, Rout PR, Dubey B, Meena SS, Pal P, Goel M. A critical review on biogas production from edible and nonedible oil cakes Biomass Convers Biorefinery. 2021: doi: 10.1007/s13399-021-01292-5.

- [21]Ramachandran S, Singh SK, Larroche, Soccol CR, Pandey A. Oil cakes and their biotechnological applications -A review. Bioresour. Technol.2007; 98(10); 2000–2009. doi: 10.1016/j.biortech.2006.08.002.

- [22]Lawler K, Hammond-Kosack K, Brazma A, Coulson RMR. Genomic clustering and co-regulation of transcriptional networks in the pathogenic fungus Fusarium graminearum. BMC Syst. Biol.2013; 7(1). doi: 10.1186/1752-0509-7-52.

- [23]Zhang QW, Lin LG, Ye WC. Techniques for extraction and isolation of natural products: A comprehensive review. Chinese Med. (United Kingdom) 2018; 13(1):1–26 doi: 10.1186/s13020-018-0177-x

- [24]Naik K, Mishra S, Srichandan SH, Singh PK, Choudhary A. Microbial formulation and growth of cereals, pulses, oilseeds and vegetable crops. Sustain. Environ. Res. 2020;30(1). doi: 10.1186/s42834-020-00051-x.

- [25]Gupta A, Sharma A, Pathak R, Kumar A. Solid State Fermentation of Non-Edible Oil Seed Cakes for Production of Proteases and Cellulases and Degradation of Anti-Nutritional Factors. J food Biotechnol Res 2018;(2):1–4.

- [26]Ancuta P , Sonia A. Oil press-cakes and meals valorization through circular economy approaches A review. Appl. Sci.2020; 10(21):1–31. doi: 10.3390/app10217432.

- [27]Steinkraus KH, Handbook of indigenous fermented foods. M Dekker Inc, New York, 1983.

- [28]Jathanna HM, Rao V, Goveas LC. Exploring Pongamia seed cake hydrolysate as a medium for microbial lipid production by Aspergillus ochraceus. Biocatal. Agric. Biotechnol. 2020;24(101543). doi: 10.1016/j.bcab.2020.101543.

- [29]Balan V, Rogers CA, Chundawat SPS, Sousa LDS, Slininger PJ, Gupta R, et al.

- [30]Conversion of extracted oil cake fibres into bioethanol including DDGS, canola, sunflower, sesame, soy, and peanut for integrated biodiesel processing. JAOCS, J. Am. Oil Chem. Soc.2009; 86(2):157–165. doi: 10.1007/s11746-008-1329-4.

- [31]Ben-Youssef S, Fakhfakh J, Breil C, Abert-Vian M, Chemat F, Allouche N. Green extraction procedures of lipids from Tunisian date palm seeds. Ind. Crops Prod.2017;(108)520–525, doi: 10.1016/j.indcrop.2017.07.010.

- [32]Deepanraj B, Senthilkumar N, Ranjitha J. Effect of solid concentration on biogas production through anaerobic digestion of rapeseed oil cake, Energy Sources, Part A: Recovery, Utilization, and Environmental Effects.2021; 43(11): 1329-1336.

- [33]Neiva IP, Silva AA, Resende JF, Carvalho DCR, de Oliveira DMS, Maluf WR. Tomato genotype resistance to whitefly mediated by allelochemicals and Mi gene. Chil. J. Agric. Res.2019;79(1):124–130.

- [34]Sharma S,Verma M, Prasad R, Yadav D. Efficacy of nonedible oil seedcakes against termite (Odontotermes obesus). J. Sci. Ind. Res. (India).2011;70(12); 1037–1041. doi:10.1016/B978-0-12-819304-4.00018-X

- [35]Bharathidasan ES, Chandrasekaran D, Natarajan A, Ravi R, Viswanathan K. Non-starch polysaccharides and phytate phosphorus content of commonly available poultry feed ingredients. J Vet Anim Sci. 2008;(5):20–24. doi.org/10.1007/978-981-15-4716-4_5

- [36]Sumantha A, Sandhya A, Szakacs C, Soccol G, Pandey CR. Production and partial purification of a neutral metalloprotease by fungal mixed substrate fermentation. Food Technol. Biotechnol. vol.2005; 43(19):313–319.

- [37]Nagegowda DA, Gupta P. Plant Science Advances in biosynthesis, regulation, and metabolic engineering of plant specialized terpenoids. Plant Sci. 2020; 294-296. doi: 10.1016/j.plantsci.2020.110457.

- [38]Mahanta NK, Gupta A.Production of protease and lipase by solvent tolerant Pseudomonas aeruginosa PseA in solid-state fermentation using Jatropha curcas seed cake as substrate Bioresour.2008;1729‐1735.

- [39]Antu KA, Riya MP, Mishra A, Anilkumar KS, Chandrakanth CK, Tamrakar AK, et al. Antidiabetic property of Symplocos cochinchinensis is mediated by inhibition of alpha glucosidase and enhanced insulin sensitivity. PLoS One. 2014 ;9(9):e105829.

- [40]KS, Shashidhara & Rani, Usha & Ananda, S. & Govindaiah, Shobha. Biodiesel Production From Simarouba Deoiled-Cake By Transesterification And Phytochemical Analysis.2017;(7)2321–3272.

- [41]Hakeem KR, Jawaid M, Alothman OY. Agricultural biomass based potential materials. Springer International. 2015.

- [42]Saini GA, Bhattacharya V. Effectiveness of sal deoiled seed cake as an inducer for protease production from Aeromonas sp. S1 for its application in kitchen wastewater treatment. Appl Biochem Biotechnol. 2013;170(8):1896–1908. doi:10.1007/s12010-013-0323-y.

- [43]Emtiazi AR, Habibi G, Taheri MH. Production of thermostable extracellular lipase by Pseudomonas grown on cotton cake and cod removal of sunflower oil waste. Fresenius Environ. Bull. 2018;(12): 704–708.

- [44]Ramachandran A, Roopesh S, Nampoothiri K, Szakacs G, Pandey. Mixed substrate fermentation for the production of phytase by Rhizopus spp. using oilcake as substrates. Process Biochem.2005;40(5):1749–1754.

- [45]Joo CS, Kumar HS, Park CG, Kim S, Paik KT, Chang SG. Optimization of the production of an extracellular alkaline protease from Bacillus horikoshii. Process Biochem.2002;382(2): 155–159; doi: 10.1016/S0032-9592(02)00061-4.

- [46]Ramachandran A, Patel S, Nampoothiri A K, Francis K M, Nagy F, Szakacs G , et al. Coconut oil cake – the potential raw material for the production of a-amylase. Bioresour. Technol. 2004; 164–174.

- [47]Ong LGA, Abd-Aziz S, Noraini S, Karim MIA, Hassan MA. Enzyme production and profile by Aspergillus niger during solid substrate fermentation using palm kernel cake as substrate. Appl. Biochem. Biotechnol. Part A Enzym. Eng. Biotechnol. 2004;(118):73–79. doi: 10.1385/ABAB:118:1-3:073.

- [48]Farzana K. Shah SN, Butt FB, Awan SB. Biosynthesis of bacitracin in solid-state fermentation by Bacillus licheniformis using defatted oil seed cakes as substrate. Pakistan J. Pharm. Sci.vol. 2005;55–57. doi.org/10.1002/jsfa.9542

- [49]Agarwal AGG, Dinesh K, Phundan Singh, Mukta Chakrabarty. Cottonseed oil quality,utilization and processing. Central Institute for Cotton Research. CICR Tech. 2003; (25 )1–16. doi: 10.1016/j.biortech.2006.08.002

- [50]Sircar PK, Sridhar A, Das P. Optimization of solid state medium for the production of clavulanic acid by Streptomyces clavuligerus.1998; 33(3):283–289. doi: 10.1016/S0032-9592(97)00.

- [51]Deshmukh SJ, Bhuyar LB. Transesterified Hingan (Balanites) oil as a fuel for compression ignition engines.Biomass and Bioenergy.2009;33(1):108–112. doi:10.1016/j.biombioe.2008.04.017.

- [52]Gutiérrez C, Rubilar M, Jara C, Verdugo M, Sineiro J, Shene C. Flaxseed and flaxseed cake as a source of compounds for food industry. J. Soil Sci. Plant Nutr.2010;10(4), 454–464. doi: 10.4067/S0718-95162010000200006.

- [53]Vidyarthi RY, Tyagi AS, Valero D, Surampalli JR, Studies on the production of B. thuringiensis based biopesticides using wastewater sludge as a raw material. Water Res. 2002; 36 (19) 4850–4860. doi: 10.1016/s0043-1354(02)00213-0.

- [54]Tuli JF, Sethi A, Khanna RP, Marwaha PK, Kennedy SS. Lactic acid production from whey permeate by immobilized Lactobacillus casei. Enzym. Microb. Technol.1985;7 (4):164–168. doi: 10.1016/0141-0229(85)90058-4.

- [55]Ohtsuki A, Akiyama T, Shimoyama J, Yazaki T, Ui SIS, Hirose SY, et al. Increased production of antioxidative sesaminol glucosides from sesame oil cake through fermentation by Bacillus circulans strain YUS-2. Biosci. Biotechnol. Biochem. 2003; 67(10); 2306–2308. doi.org/10.1016/j.neures.2006.06.005

- [56]S. Adiloğlu et al. We are IntechOpen the world’s leading publisher of Open Access books Built by scientists. scientistsIntech tourism. 2012 (1)13. doi: 10.1016/j.colsurfa.2011.12.014.

- [57]Li H, Deng Z, Wu T, Liu R, Loewen S, Tsao R. Microwave-assisted extraction of phenolics with maximal antioxidant activities in tomatoes. Food Chem.2012;130(4): 928–936. doi: 10.1016/j.foodchem.2011.08.019.

- [58]Surendra BS , Veerabhadraswamy M. Microwave-assisted synthesis of the polymer via bio platform chemical intermediate derived from Jatropha deoiled seed cake. J. Sci. Adv. Mater. Devices.2017; 2(3) 340–346. doi: 10.1016/j.jsamd.2017.07.004.

- [59]Hessle A, Eriksson M, Nadeau E, Turner T. Cold-pressed hempseed cake as a protein feed for growing cattle. Acta Agric Scand Sect A Anim Sci.2012; (48):136–145. doi.org/10.5713%2Fajas.2012.12213

- [60]Mustafa MJ, Christensen DA. Effects of moist heat treatment on crude protein composition and degradability of field peas. Can J Anim Sci. 1998;(78):453–456. doi.org/10.1016/S0377-8401(02)00136-0

- [61]Lunger CS, McLean E, Gaylord TG, Kuhn D. Taurine supplementation to alternative dietary proteins used in fish meal replacement enhances the growth of juvenile cobia( Rachycentron canadum). Aquaculture.2007; 201–210. doi.org/10.1007/s10695-017-0459-8

- [62]allaway JC. Hempseed as a nutritional resource: An overview’. Euphytica, 2004;(140):65–72. doi:10.1007/s10681-004-4811-6

- [63]Suja AC, John KP, Selvam TA, Jayalekshmy NTA. Antioxidant efficacy of sesame cake extract in vegetable oil protection. Food Chem.2004; (84):393–400;2004. doi: 10.1016/S0308-8146(03)00248-6.

- [64]Adebona OM, Ogunsua AO. Development of conophur nut-based cereal snack food I –Biscuits. J Food Agric. 1988;123–126. doi.org/10.1007/s13197-014-1386-7

- [65]Guéguen G, Pascal L. Organic Foods. In Reference Module in Biomedical Sciences Encyclopedia of Human Nutrition.1997; 413–416. doi: 10.1016/B978-0-12-801238-3.99501-1.

- [66]Sunil L, Appaiah P, Prasanth Kumar PK, Gopala Krishna GK. Preparation of food supplements from oilseed cakes. J. Food Sci. Technol.2015;52 (5): 2998–3005. doi: 10.1007/s13197-014-1386-7.

- [67]Mordenti AL, Giaretta E, Campidonico L, Parazza P, Formigoni A. A review regarding the use of molasses in animal nutrition. Animals.2021;11(1): 1–17. doi: 10.3390/ani11010115.

- [68]Nguyen TV, Schöfer W, Bormann J. The stress-activated protein kinase FgOS-2 is a key regulator in the life cycle of the cereal pathogen Fusarium graminearum. Mol. Plant-Microbe Interact. 2012;25(9):1142–1156. doi: 10.1094/MPMI-02-12-0047-R.

- [69]Sunil AG, Appaiah L, Kumar P, PK, Krishna G. Development of Health Foods from Oilseed Cakes. J. Food Process. Technol. 2016; 7(11): 631–640. doi: 10.4172/2157-7110.1000631.

- [70]Bano S, hashirekha Z, Rajarathnam MN. Improvement of the bioconversion and biotransformation efficiencies of the oyster mushroom (Pleurotus sajor-caju) by supplementation of its rice straw substrate with oilseed cakes. Enzyme Microb. Technol.1993; 15 (11): 985–989. doi: 10.1016/0141-0229(93)90176-3.